Method and Device for Treating Water from Pavement Cutting

Patent Application 2016-112894 / Published 2017-217593

View on Google Patents open_in_newWe support essential infrastructure such as extending the lifespan of concrete structures and maintaining lifelines,

delivering a safe and secure society through cutting-edge technology.

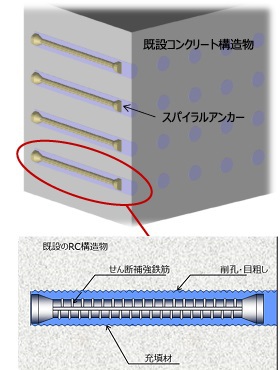

The spiral anchor method is a shear reinforcement method for existing concrete structures. This is a simple construction method that is completed by drilling an existing frame and roughing the inner surface of the drilled hole, injecting a fixing agent, and inserting and fixing reinforcing bars. By using a special bit to roughen the hole wall surface in a spiral shape and using a TP nut reinforcing bar as the reinforcing reinforcing bar, the fixing strength with the existing frame is improved and reliable shear reinforcement is possible.

<View Resources:スパイラルアンカー工法研究会open_in_new

>

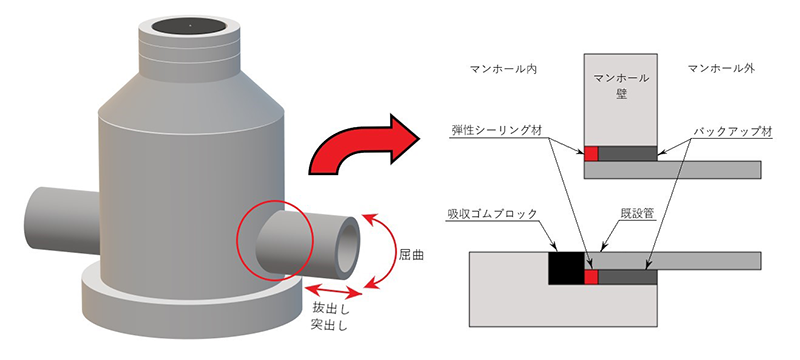

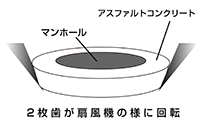

The existing human hole seismic retrofit method cuts the connection between the manhole and the tube by cutting the wall of the manhole along the outer periphery of the tube by a special cutting machine.The cut grooves are filled with backup materials to prevent the inflow of sediment and sealing materials that prevent the inflow of groundwater, and seismic retrofit of the connections. In addition, an absorption rubber block is installed in the invert part to prevent damage to the tube opening even if the tube protrudes into the manhole during an earthquake.

<View Resources:下水道既設管路耐震技術協会open_in_new

>

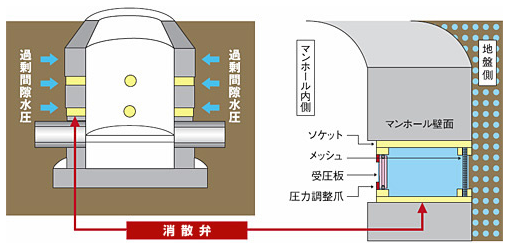

The floatless method installs a “dissipative valve” with a dedicated mounting device, instantly dissipates excess pore water pressure generated during an earthquake, suppresses the liquefaction phenomenon of the ground around the manhole, and suppresses the floating of manholes.

<View Resources:下水道既設管路耐震技術協会open_in_new

>

It is possible to suppress the floating of manholes caused by the liquefaction phenomenon of the ground that occurs during earthquakes, etc., and does not require large-scale construction in a very simple structure, it is sufficient for short-term construction work at low cost, It is a manhole levitation prevention structure that can be easily applied to existing manholes.

<View Resources:説明資料PDFを開くopen_in_new

>

The Hydrogrout method is a water-stopping and reinforcement technique in which a chemical solution, primarily composed of polyisocyanate compounds, is injected into the ground or into cracks and voids in structures. The solution penetrates these areas and reacts with water to form either a solidified mass or an elastic gel. This method is characterized by excellent water-sealing performance, long-term durability, and minimal environmental impact.

Hydrogrout A: A water-stopping agent made of chemical solution composed mainly of polyisocyanate compounds.The chemical solution mixed with the injected catalyst generates carbon dioxide gas by reacting with water, penetrates into fine voids, forming a high-strength, high-water-stopping solidentity and water-stopping layer.In addition, the cured product is chemically stable and maintains hydrophobic, so it does not dissolve in water and does not have the effect of soil contamination.

Hydrogrout L: Water-stopping agent with a chemical solution containing a polyisocyanate compound as a main component. Disperses well in water and reacts. The reacted resin rapidly hydrates and swells in volume to form a rubber elastic gel. In addition, due to foaming and surface activity (volume swelling), it penetrates well into cracks and voids in the ground and adheres firmly to soil particles, etc., so that excellent water stopping, sealing and stabilizing effects can be obtained.

<View Resources:ハイドログラウト研究会open_in_new

>

The water stop method of the leakage part of the concrete structure, one liquid system that reacts with water but does not dissolve in water, and the chemical solution is injected into the gap for rain leakage, leakage, and water stop and strengthen of the building with high safety chemical injection method.It is a chemical injection method that can exert a water stop effect for a long time, and is a one-liquid system composed mainly of polyisocyanate compounds (urethane polymers).

<View Resources:日本TACSS協会open_in_new

>

Underground tunnels, underground pits, pouring of concrete structures such as walls, elongation against leakage from cracks, etc., because the main material is petroleum resin and acrylic material excellent in adhesion strength, Even if displacement occurs in the housing due to an earthquake, the curing accelerator containing the water-absorbing urethane prepolymer is stirred and mixed immediately after injection in accordance with the opening of the joint, and the water absorption effect dramatically accelerates the curing time of the main material, and reliably stops water even with a large amount of water leakage.

The Vandex flexin method is a method of injecting extremely low viscosity acrylic two-component synthetic resin at high pressure using an injector into the leakage part of concrete.This method drills the leakage of concrete at an angle of about 45 degrees, uses a special nozzle, and an injection machine that can always press-fit a hydrophilic injection agent by a specified amount, and can be filled into the entire gap.The filled infusion becomes a high-elastic resin and provides the highest level of water stop effect.します。

<View Resources:バンデックスフレキシン工法open_in_new

>

BKU is a sheet lining method that protects concrete sewer pipelines and structures by using synthetic resin plates (BKU plates = PVC ribbed plates).

The name BKU is derived from the German words:

Beton (concrete)

Kunststoff (synthetic resin)

Unit (integration)

—literally signifying the integration of concrete and synthetic resin.

In recent years, concrete structures in sewer pipelines and wastewater treatment facilities have faced the problem of corrosion caused by sulfate ions and microorganisms contained in sewage.

As a countermeasure, various methods have been developed. Among them, BKU was specifically designed for concrete facilities that are in constant contact with water, featuring:

<View Resources:BKU工法工業会・BKU防食工法協会open_in_new

>

Ecorogard method after removing the corrosion layer of the existing manhole inner surface, by performing surface protection in the top coat coated with a cross-sectional enhancer, a composite type of manhole rehabilitation method for rehabilitation of the existing manhole.Cross-sectional enhancer to be used is high strength, the inner diameter after construction is excellent in durability without shrink diameter. Furthercross-sectional enhancer is an epoxy resin mixed with sludge incineration ash is a recycling resource, it is an environmentally friendly material.

<View Resources:エコロガード工法協会open_in_new

>

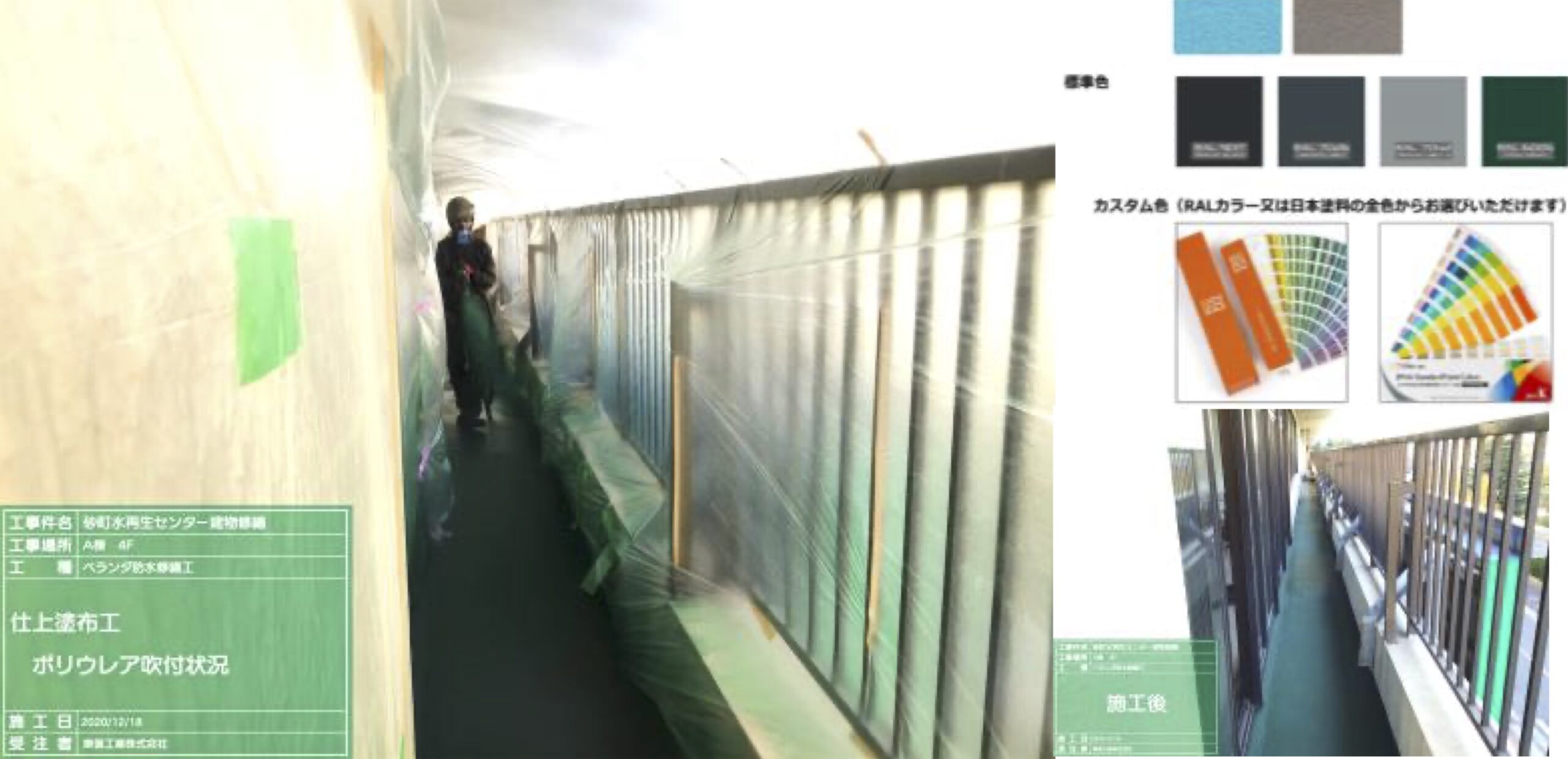

Coating material with excellent flexibility, durability, toughness, waterproofing, rust proofing, salt damage control effect, from general waterproofing treatment to fuel and more irritating chemical product storage in harsh environments, promotion and resilience of infrastructure persistence or durability, water conservation, We can provide optimal coating solutions for all projects, such as rebuilding communications and energy networks.

<View Resources:説明資料PDFを開くopen_in_new

>

The oblique SS method can cut the pavement surface in a circle by using a dedicated cutting machine, and because it is possible to apply an angle further, it can be constructed diagonally like an inverted triangular saw.In addition, because of the special cutting technology, there is no noise peculiar to the cutter.We oblique SS method not only increases the durability of the facility and extends the life, but also provides safety, ecology, urban environment and economical human hole iron lid replacement technology.

<View Resources:説明資料PDFを開くopen_in_new

>

Visualize hidden walls and underground structures using MR.

Repeatedly train on construction machinery and simultaneous multi-team operations with VR.

These technologies enable precise construction management and ensure safety on site!

Patent Application 2016-112894 / Published 2017-217593

View on Google Patents open_in_newPatent Application 2015-245304 / Published 2017-111295 / Patent 6175124

View on Google Patents open_in_newPatent Application 2012-023918 / Published 2013-159998 / Patent 5514846

View on Google Patents open_in_newPatent Application 2011-089331 / Published 2012-219582

View on Google Patents open_in_newPatent Application 2009-156810 / Published 2011-012433 / Patent 5139377

View on Google Patents open_in_newPatent Application 2008-237510 / Published 2010-070935 / Patent 4956512

View on Google Patents open_in_newApril 10, 2022

It has been confirmed that manholes may protrude from the road surface due to the liquefaction of the ground during a large earthquake. When the uplifting of a manhole occurs, it may bring about not only dysfunctions, such as the loss of the ability of sewage to flow, but also displacements, such as that of the pipeline connected to the manhole, which makes drainage difficult. However, effective and economic measures against the uplifting of existing manholes are still in the developmental stages. This study proposes a weighting method that increases the self-weight of the manhole as a countermeasure against the uplifting of manholes during an earthquake. The applicability of this weighting method will be clarified by conducting case studies from the viewpoint of the safety factor for manhole uplifting and the quantity of manhole uplifting. As a result, it is shown that, regardless of the shape of the manhole and the groundwater level, the risk of manhole uplifting during liquefaction can be reduced by implementing this weighting method.